Screw Machining for curious little ones, explained to a 7-year-old: when magic transforms metal !

A brief history of screw-cutting:

In the Middle Ages, in the age of knights, a special kind of magic was born in the village of Saint-Sigismond in Haute-Savoie, thanks to a kind gentleman called Claude-Joseph Ballaloud. He brought this magic to the watchmaking activities of the large factories in the city of Geneva. At that time, the farmers of the Valley, looking to supplement their income during the winter season, discovered the magic of screw machining and trained themselves in its techniques.

But what is this magic called screw machining?

It’s a bit like metal magic… Imagine a world where toys, cars and even robots come to life from a metal magic wand. This magic wand, which actually refers to a metal bar, is sculpted using a special machine called a “screw machine”. It’s as if a magician (known as a screw machine operator) were working with a magic wand to give shape to unique creations.

Imagine the screw machine operator as a magician programming the screw machine. The magic wand/metal bar turns on itself, and the machine magically makes small parts of it (called swarf) disappear to create a variety of shapes. This is how screw machining parts are created, a bit like carving a statue out of a large stone, but very quickly and extremely precisely.

Screw Machining is not limited to a simple magic wand. The screw machine operator can choose wands of different aspects (materials) and decide how to transform them to create incredible objects. This metallic magic is used to make products that we use every day, such as screws, highly technical bolts or the subtle parts found in watches.

And that’s not all! High precision turning is also responsible for the magic behind robots. Screw machine operators create the complex parts, such as robotic arms and gears, that bring these science-fiction creatures to life. It’s like adding a touch of magic to modern technology.

Turning can be carried out in small, medium or large production runs on screw machines known as conventional or numerically controlled automatic lathes. These machines are like the magic wands of the screw machine operator, enabling him to produce several identical objects quickly and efficiently.

The next time you play with your favourite toys or get into a car, remember that somewhere, a magician (screw-cutter) worked with his screw-cutting machine to bring these magical objects to life. Each object has its own magical story of manufacture, thanks to the magic of screw-cutting. It’s as if a small part of this magic is present in every aspect of our daily lives, making the world a little more enchanting and fascinating. 🪄✨

Read more news

Your frequently asked questions !

Your frequently asked questions !Optimise your production with SadevTEQ: A trusted partner for your machined parts Machined parts play a crucial role in many industries, from aerospace and hydraulics to locksmithing and electronics. When you're looking for a reliable...

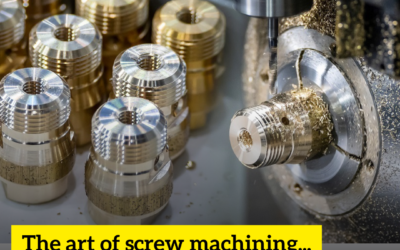

The Art of Screw machining: When Precision Becomes Crucial with SadevTEQ

The Art of Screw machining: When Precision Becomes Crucial with SadevTEQScrew machining is a technique for manufacturing mechanical parts where precision is paramount. It is essential to the manufacture of components for a variety of industries including aerospace,...

Screw machining and ecology: an alliance for a green future

Screw machining and ecology: an alliance for a green futureScrew machining is a technique for manufacturing metal parts used in many industries, including automotive, aerospace and electronics. Although this technique is essential to produce precision components, it...